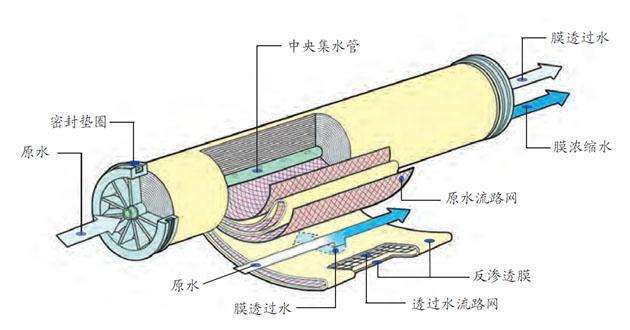

Reverse osmosis membrane element

Product Introduction

The reverse osmosis membrane material is mainly the core element to achieve the reverse osmosis effect. It is an artificial semi permeable membrane with certain characteristics made of a simulated biological semi permeable membrane. It is generally made of polymer materials. For example, cellulose acetate membrane, aromatic polyhydrazide membrane, aromatic polyamide membrane. The diameter of the surface micropores is generally between 0.5 and 10 nm, and the permeability is closely related to the chemical structure of the membrane itself. Some polymer materials have good salt repellency, but the water quality transmission speed is not very good. Some polymer materials have more hydrophilic groups in their chemical structures, so the water permeability is relatively fast. Therefore, a satisfactory reverse osmosis membrane should have an appropriate amount of penetration or desalination rate.

Product Features

It has high desalting rate at high flow rate.

It has high mechanical strength and service life.

Capable of functioning under low operating pressure.

Resistance to chemical or biochemical effects.

It is less affected by pH value, temperature and other factors.

The raw materials for film making are simple in source, simple in processing and low in cost.

The structure of reverse osmosis membrane includes two types: asymmetric membrane and homogeneous membrane. At present, cellulose acetate and aromatic polyamides are the main membrane materials used. Its components are hollow fiber type, roll type, plate frame type and tube type. It can be used for chemical unit operations such as separation, concentration and purification, mainly for pure water preparation and water treatment industries.