Multi medium filter

[Introduction]

The meaning of filtration. In the process of water treatment, filtration generally refers to the process of intercepting the suspended impurities in the water left by the multi-media filter with filter material layers such as quartz sand and anthracite, so as to make the water clear. The porous material used for filtering is called filter material, and quartz sand is the most common filter material. There are many kinds of filter materials, such as granular, powdery and fibrous. Common filter materials include quartz sand, anthracite, activated carbon, magnetite, garnet, ceramics, plastic balls, etc.

Multi media filter (filter bed), which uses more than two media as the media filter of the filter layer, is used in the industrial circulating water treatment system to remove impurities in sewage, adsorb oil, etc., so that the water quality meets the requirements of recycling. Filtration is mainly used to remove suspended or colloidal impurities in water, especially micro particles and bacteria that cannot be removed by sedimentation technology. BOD5 and COD can also be removed to some extent.

[Composition]

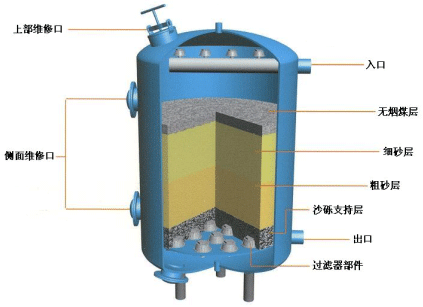

The multi-media filter is mainly composed of the filter body, supporting pipelines and valves.

The filter body mainly includes the following components: simple body; Water distribution components; Support components; Backwash air pipe; Filter material; Exhaust valve (external), etc.

Function

Remove the sludge, suspended solids, colloids and other organisms in the water, and reduce the mechanical damage and pollution to the reverse osmosis membrane elements.

[Composition of inner filter]

The multi-media filter materials in the filter are high-quality homogeneous gravel, quartz sand, magnetite, anthracite and other filter materials. These filter materials are scientifically and orderly distributed in the filter tank according to their specific gravity and particle size. For example, anthracite with small specific gravity and slightly larger particles is placed on the top layer of the filter bed, quartz sand with moderate specific gravity and small particle size is placed on the middle layer of the filter bed, and gravel with large specific gravity and particle size is placed on the bottom layer of the filter bed. This ratio ensures that the filter will not have disordered layers during backwashing, thus ensuring the retention capacity of the filter material.

[Features]

Porous media filters are widely used in water treatment processes and can be used alone, but most of them are used as prefilters for advanced water treatment (exchange resin, electrodialysis, reverse osmosis).

Multi medium filter is a common pretreatment device for deep water purification, and different filter materials can be added according to process requirements.

The multi-media filter can be made of glass fiber reinforced plastic, A3 steel anti-corrosion or rubber lining, and all stainless steel. There are two modes of operation: fully automatic and manual. Automatic control adopts automatic controller and pneumatic and hydraulic valve control, which is easy to operate

It is easy to maintain, and is widely used in pre-treatment devices of water treatment process in all walks of life.

The filtering materials of the multi-media filter (including the dual media filter) shall have sufficient chemical stability. The relative density and particle size of each medium shall be different. The dual media filter consisting of anthracite and quartz sand uses anthracite with a relative density of 1.4-1.6, particle size of 0.8-1.8 mm, quartz sand with a relative density of 2.6-2.65, and Li Jingwei with a particle size of 0.5-1.2 mm; In addition to the above two filter materials, the 3-layer filter can also use heavy ores such as matte and magnetite, with a relative density of 4.7-5.0 and a particle size of 0.5-4.0mm.